An objective evaluation considering CO2 emissions and energy input when using wood as a fuel

Introduction

The way of sawdust drying and the respective energy input play a decisive role in the pellet production process. Economical and ecological aspects are to be taken into account to determine the most appropriate drying technology. This means that the primary energy consumption and the produced CO2 emissions influence the decision what drying method to use when wood is used as fuel. The energy-based production costs can be specified on the basis of the energy input. In this regard, the type of energy carrier used is relevant too. CO2 emissions represent a cost factor to some purchasers of industrial pellets in Europe as well which is due to the trade in CO2 certificates. Power plants with a low primary energy input and low CO2 emissions hold clear competitive advantages and are thus future-oriented.

Energy input during pellet production

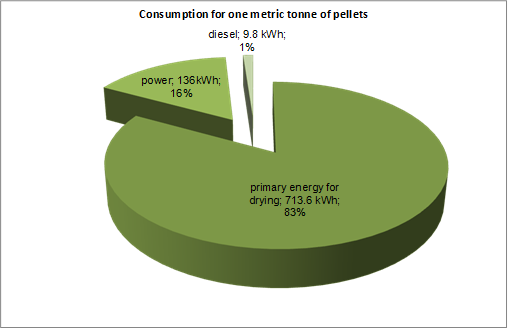

The following figure shows the general amount of energy consumed when manufacturing one metric tonne of pellets from wet sawdust (50% water content). It is approximately 17.5% referring to the amount of energy (lower heating value) contained in the pellet.

Figure 1: Calculated energy input for the production of one metric tonne of pellets from sawdust

The biggest proportion (83%) of the energy is required for drying. This figure, however, neglects the fact that the required electrical power is also produced from primary energy. If the overall energy input is examined in terms of primary energy input, the following figure results.

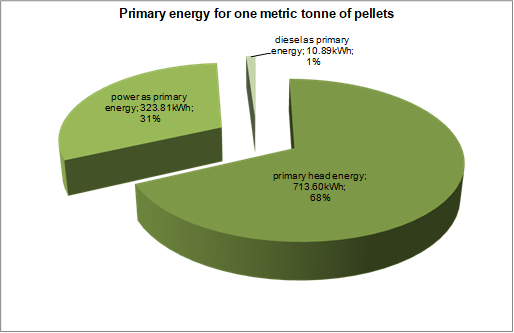

Figure 2: Calculated primary energy input for pellet production (42 % primary energy efficiency acc. to UBA 2012)

If the electrical power requirement is measured as primary energy too, conversion losses are to be considered and the respective proportion of primary energy increases from 16% to 31%.

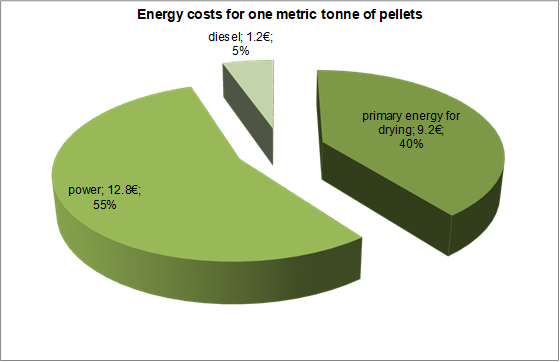

This shows clearly that it can be reasonable to use residues from the pellet production process and forest wood residues in an own power production facility. The ratio of heat and power generation is ideal in a combined heat and power plant (CHP plant). When analyzing the costs for energy purchases, it becomes even clearer how interesting a CHP plant is. Figure 3 shows the costs of an average sized pellet production plant (output of 120.000 t/a).

Figure 3: Calculated energy costs for pellet production from sawmill by-products (values from 2009)

The electricity costs represent the biggest cost block of the energy input. It is, however, disregarded that the electricity price increases by about 5% per year. Thus, the electricity costs grow more strongly by about 3% since the cost for heat generation only increase by 2 % (price increase of wood).

Comparison of drying technologies

Besides determining the standard parameters such as investment and operating costs, a large-scale evaluation is reasonable to find the appropriate drying technology for the respective plant site. It should be evaluated for example, if an own power production facility is economically reasonable. When power is generated in a biomass combined heat and power plant, the choice of drying technologies, however, is limited. Low temperature drying systems in the form of belt dryers can only be used economically in CHP plants. In contrast to that it is possible to use a directly or an indirectly-fired drum dryer or a tube bundle dryer for pellet production plants without a combined heat and power plant.

The following table shows the advantages and disadvantages of a belt dryer and a directly-fired drum dryer.

| Belt dryer | Directly-fired drum dryer | ||

| + | Drying at low temperatures, i.e. no discoloration and reduction in quality of dry product | + | Exhaust air cleaning by means of WESP and RTO possible |

| + | No insertion of pollutants from combustion (gases and ashes) into dry product | + | Lower raw material consumption for heat generation |

| + | Lower fire risk inside dryer and thus higher dryer availability | – | Higher fire risk inside dryer and thus higher risk of plant shut-downs |

| + | No use of fossil energies for exhaust air cleaning | – | High use of fossil energies for exhaust air cleaning |

| – | Due to high exhaust air flows no exhaust air cleaning possible, thus emission of low temperature VOC | – | Drying at high temperatures, i.e. risk of discoloration and reduction in quality of dry product |

| – | Higher raw consumption for heat generation | – | Insertion of pollutants from combustion (gases and ashes) into dry product |

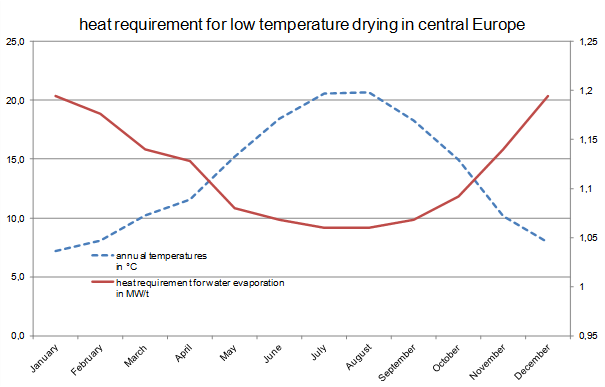

Moreover, the amount of energy required for low temperature drying is slightly higher and depends strongly on the outside temperature.

- The energy consumption of a directly-fired drum dryer is at about 0.9 MWh/t of water evaporation.

- Depending on the climatic conditions a belt dryer requires between 0.7 and 1.5 MWh/t of water evaporation.

The following figure shows the heat requirement of a belt dryer at a European plant site in dependence of the outside temperature.

Figure 4: Example for the heat requirement of a belt dryer

At first sight, the belt dryer seems to have minor disadvantages compared to the directly-fired drum dryer. However, the profitability of a belt dryer combined with a power plant increases significantly, if

- the electricity costs and/or feed-in tariffs are high and a power plant can thus be operated economically,

- the quality of the dry sawdust and the ash content of the sawdust (after drying) are relevant for the use of the pellets,

- the emissions of the directly-fired drum dryer have to be reduced by means of an RTO (regenerative thermal oxidation) using fossil gas.

If one of the aforementioned aspects applies, the installation of a biomass CHP plant for own power generation has to checked thoroughly.

Comparison CO2 emissions

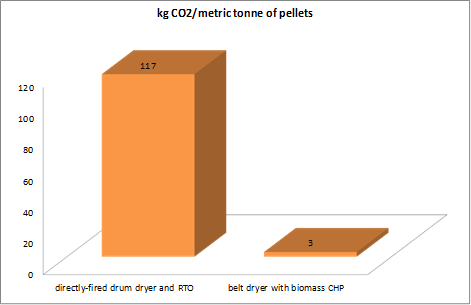

It is reasonable to examine the various drying technologies and the respective emissions. A comparison reveals that the CO2 emissions of a belt dryer with power generation from biomass are significantly lower than those of a directly-fired drum dryer with RTO and power supply from the public grid.

When comparing the CO2 emissions of a drum dryer with those of a belt dryer and own power generation from biomass with grid power supply, it becomes obvious that the emissions in the case of the option ‚belt dryer plus own power generation ‘are significantly lower. Instead of releasing CO2 emissions of 117 kg/metric ton of pellets only about 3 kg CO2/metric ton of pellets are to be expected for the option ‘CHP plant plus belt dryer’.

Figure 5: Comparison of calculated CO2 emissions of a belt dryer with CHP plant and a directly-fired drum dryer with RTO and grid power supply (only energy-related emissions)

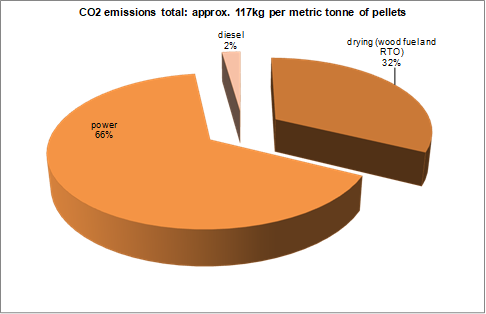

If drying takes place in a biomass-fired drum dryer, CO2 emissions only result from using liquid gas for RTO operation. The installation of an RTO is required in the U.S. for specific tree species (e.g. Southern Yellow Pine). The CO2 emissions resulting from the wood used to generate energy for drying have been neglected in this evaluation. As it is impossible to use heat in form of low temperature, additional CO2 is emitted due to using non-regenerative primary energies to generate power for the drying plants.

Figure 6: Calculated CO2 emissions of a directly-fired drum dryer with RTO without CHP plant

565 g/kWh for German power mix as of 2009,source: Federal Environmental Agency, FG I 2.5., as of March 2011

Summary

The aforementioned considerations have to be taken into account when making a decision on the appropriate drying technology. Short-sighted plant concepts will turn out to be economically inefficient as soon as they have to compete with other concepts benefitting from low primary energy input and cost-effective regenerative energies. Moreover, price increases of fossil energies range between 5% to 8% per year, whereas regenerative energies only have a 3 to 4% increase per year. Thus, price increases have to be considered for any profitability analysis.

To conclude, a thorough profitability analysis is a key element in the decision whether to build a pellet production plant with or without energy production. The drying technology chosen plays a decisive role in this regard, since it seriously influenced the energy costs, which represent about 10 to 25% of the production costs.

As a consequence, an objective and supplier-independent party should make an informed decision on the best drying technology to be used.

Explaining all this to you gives you a small overview about the key points of using bioenergy and explained hopefully the advantages of bioenergy and biomass energy to all human being. In the future it is more than important that not only the production of renewable energy, like wind and solar will increase, we also need to implement in our energy system an easy storable renewable energy like biomass.

We are your partner to gain this target. Let’s do it together!